- Home /

- 14 Advantages

14 Advantages

6) Lifetime Warranty

Windblox is the only manufacture warranting against buffs and abrasions. Your windscreen will be clear for the lifetime of your automobile. 7) No Squeaks or Rattles

Windblox windblockers are securely held in place, with no movement between the windscreen and your car. This prevents annoying high pitch squeaks and rattles when driving with your windscreen 8) Easy Installation

This wind deflector is most simple to install. A 12-year old niece of a staffer installs these windscreens in two minutes.p 9) Does Not Induce Abrasion Against Your Car

Windblox windstop does not rub against your car, preventing ongoing abrasion and wear. This is a picture from a customer's car. She purchased a windscreen from a different vendor. After eight months continually mounted on her car, the poor fit caused accumulated wear against the roll hoopsp 10) Does Not Yellow from Sun Exposure

At one point, this windscreen (from another vendor) was clear. This customer lives in Texas, and had this windscreen mounted on his car for four years, before it became unusable. Windblox windscreens are guaranteed not to yellow from sun exposure. 11) Anti Wobble

No wobble. Windblox windblockers remain secure when in use. The windscreen does not wobble or vibration when, even at high speeds. 12) Made For Speed

Windblox wind deflectors are rated for 150 MPH (250 KM/hr). 13) Utilitizes Green Processes

All cast-off material is recycled. Base material incorporates soybean based oils instead of all petroleum, increasing use of renewable materials. 14) Laser Fabrication

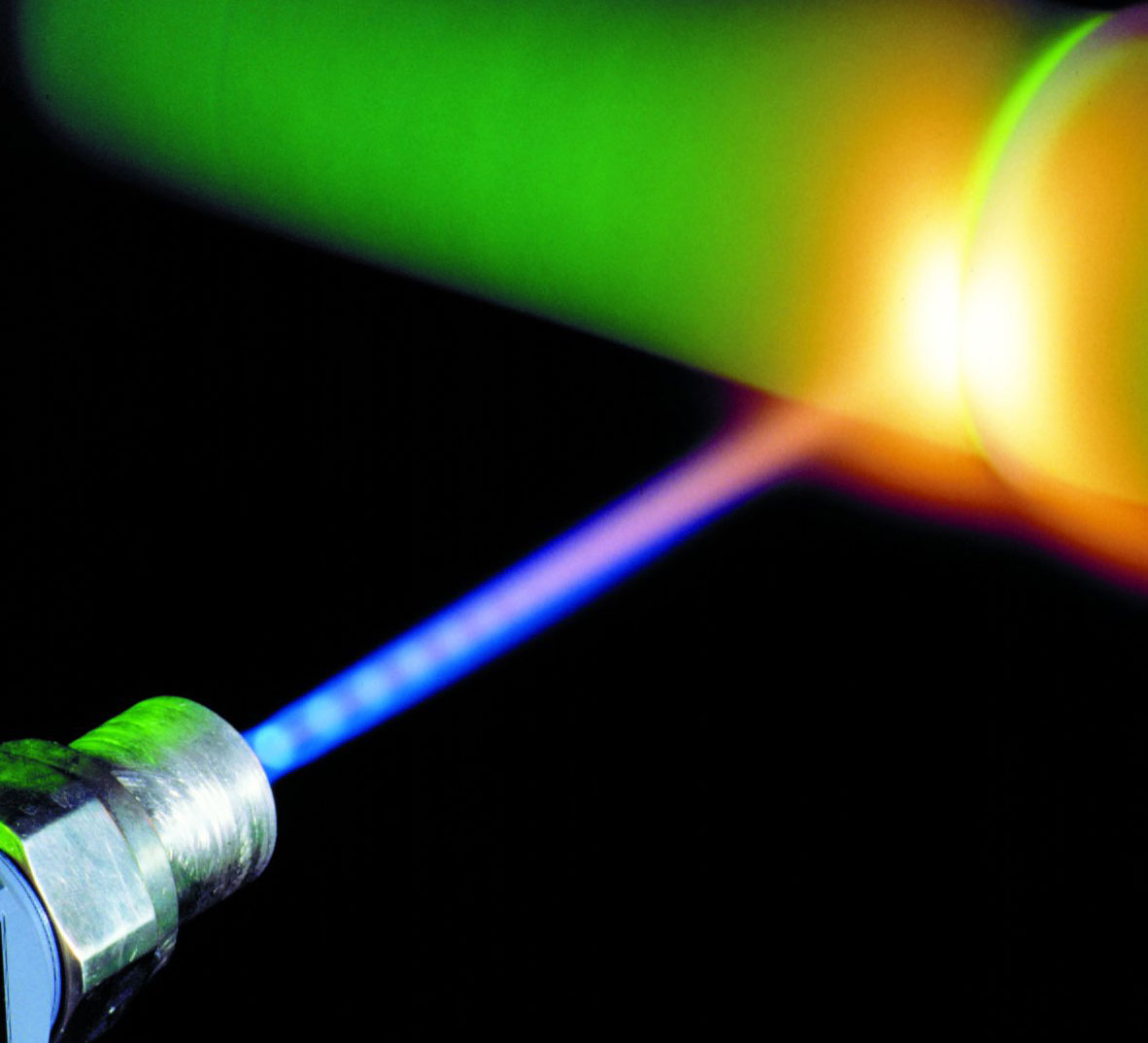

All Windblox wind deflectors are cut on a 5,000 watt laser (normal power for this process is 100 watts), providing exceptionally clear cuts. |

|||||||||||||||||||||